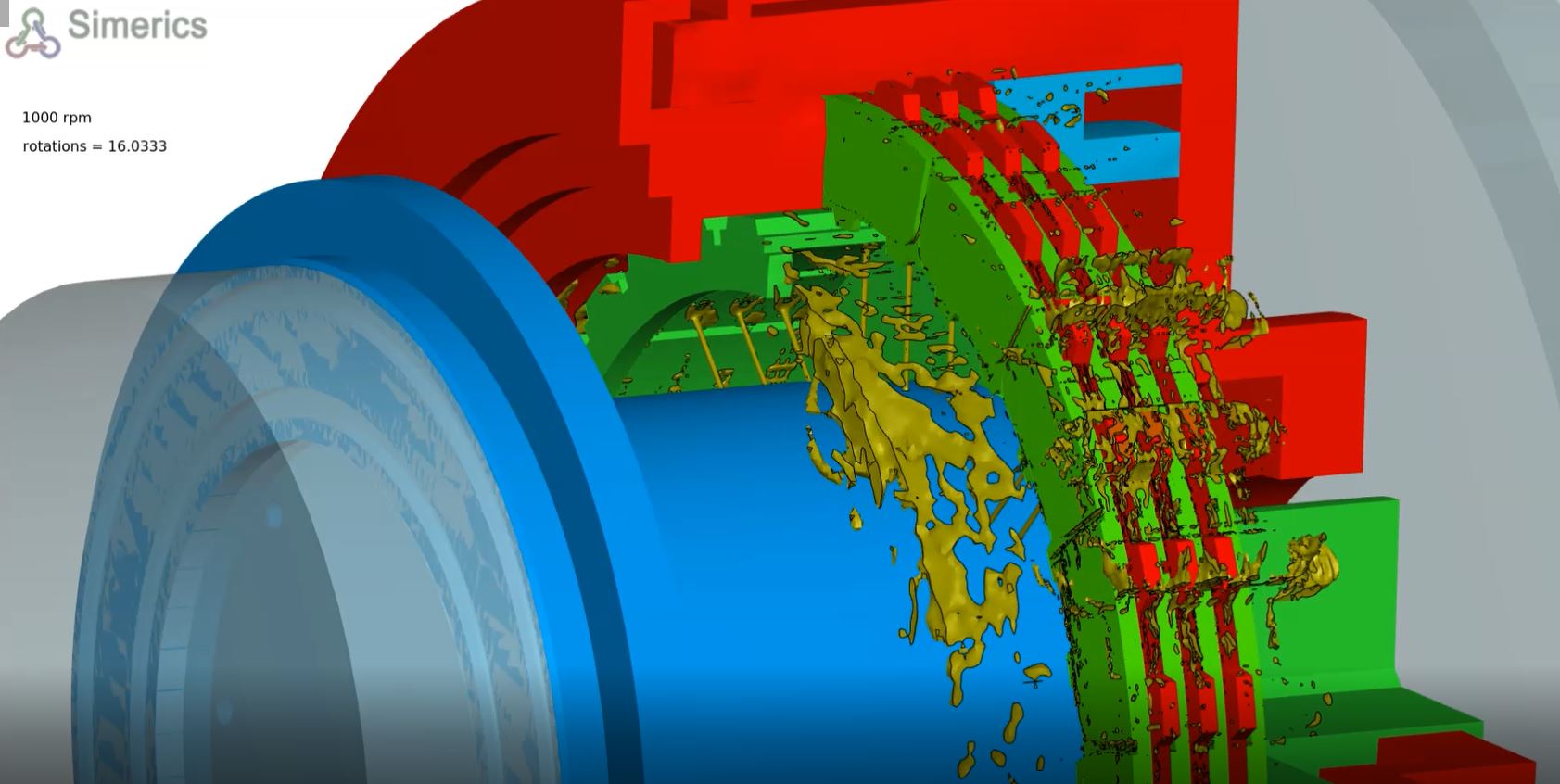

As a result of several rotating components and multiphase conditions, gearboxes and clutches are extremely difficult machines from the perspective of simulation. The multiphase flow-field permanently in interaction with the rotating parts, which leads to numerical difficulties. Additionally, physics like cavitation and heat-transfer must be taken into consideration.

By implementing CFD Simulation in the development process, gearboxes and clutches can be investigated and understood more in detail. Critical geometrical layouts may be analyst before purchasing parts, which reduces cost and speeds up the time-to-market.

After successful simulation, all fluidmechanical information such as pressure, temperature or velocity distribution are available for evaluation. In addition, calculated system information like system losses or efficiency can be analysed and compared to older designs. Beyond system investigation, CFD can perfectly be used to understand or optimize details. For this purpose, only parts can be visualized or calculated separately.

Complex geometry

- Many components

- Several components move relative to each other

- Small gaps and clearances

- Several different flow paths

Complex physics

- Multi-phase flow with free surfaces

- Transient approach necessary

SIMERICS MP provides a fast, accurate and reliable multiphase CFD tool for gearbox and clutch simulation, also including templates to speed-up the development process. In order to reduce simulation time, MP supports MPI for multicore computing.

What kind of fluidmechanical information can be simulated by SIMERICS MP?

- Volume flows, mass flows

- Losses, torques, performance

- Pressure and pressure losses

- Oil distributions

Our customers use SIMERICS MP for to investigate:

- Influence of external acceleration on the oil supply

- Oil supply for bearings

- Oil wetted areas

- …

Take a look at our sample applications or contact our experts for gear boxes and clutches – we would be happy to talk to you.